At Nyle, our unwavering commitment has always been to support kiln owners in their quest for improved efficiency and productivity in lumber drying.

Conventional kilns have long grappled with a significant drawback - heat loss through venting. The necessity of venting to remove excess moisture results in substantial energy wastage. This not only hampers efficiency but also drives up energy costs, leading to wood quality degradation.

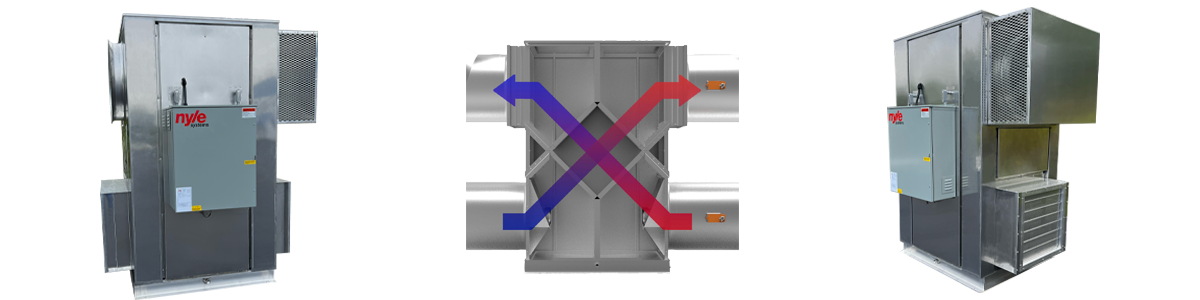

Our revolutionary dynamic heat recovery vents address this pressing issue by recovering the lost energy during drying. These cutting-edge heat exchangers are designed to transfer a large portion of the outgoing vented air's energy to the incoming air. By harnessing energy that would otherwise go to waste, the need for frequent "reheating" is drastically reduced. As a result, overall fuel consumption is minimized by a minimum of 15%, leading to substantial energy savings.

Unparalleled Efficiency: Say goodbye to excessive heat loss through venting. Our heat exchangers optimize energy usage, ensuring your kiln operates at peak efficiency throughout drying.

Cost-Effective Solution: By significantly reducing fuel consumption, our dynamic heat recovery vents lead to tangible cost savings on your energy bills. Experience the benefits of a more cost-effective lumber drying operation.

Improved Wood Quality: With better energy management, the drying process becomes more consistent, leading to superior wood quality and reduced degradation.

Join countless kiln owners who have already embraced Nyle's heat recovery vents to revolutionize their lumber drying process. Take the first step towards enhanced efficiency and sustainable practices in kiln drying. Embrace the future of lumber drying with Nyle today!